Features

- Features

- Home

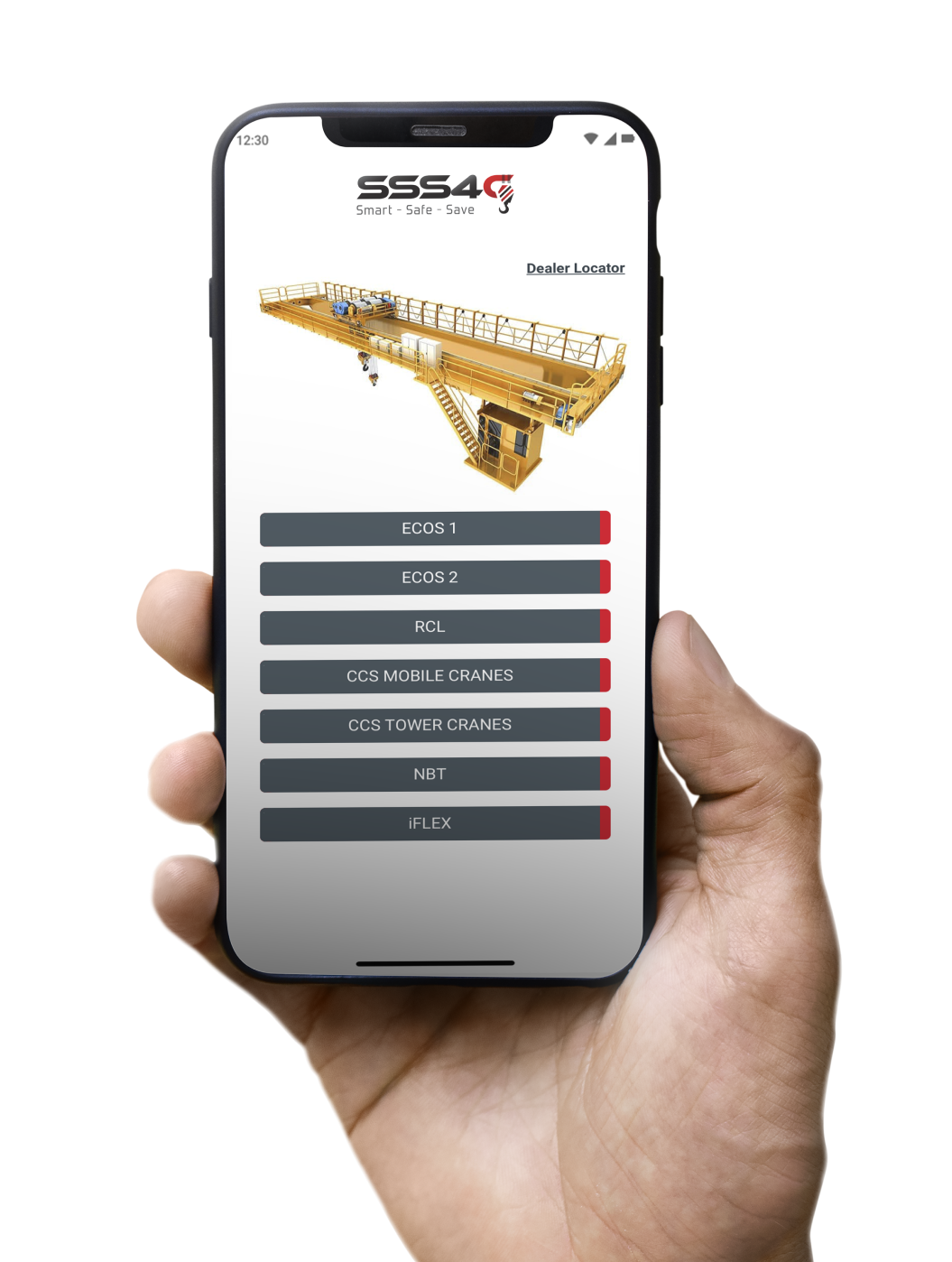

If you own a crane, then you know how important it is to keep it in top condition. SSS4C is a portal that gives you quick and easy access to all the information you need to keep your crane in top condition. With SSS4C, you can track maintenance records, schedule repairs, and get real-time alerts if there are any issues with your crane.

By applying IoT technology, any mechanical changes within the equipment will be recorded and sent to crane and hoist operators via an attached integrated sensor (magnetic-inductive) and monitoring device. While cranes and hoists are operating, individual signals from sensors can be extracted and sent to user’s phone for analysis. The portal gives users a transparent view of all maintenance activities and alerts.

Motor temperature

Percentage remaining of a brake based on its designed working period

Percentage remaining of a hoist designed working period

Hoist brake wear

Voltage supply

Phase order: main supply fault, incorrect phase order (phase order display)

If the calculated relative safe working period percentage is less than zero

If the number of hoist starts has exceeded the design limit

If the value for the hoist run time has exceeded the design value

If the calculated value for the brakes safe working period percentage is less than zero

If the number of interrupted stops has exceeded the design limit

If the number of control actions has exceeded the design limit

Wire rope condition

SSS4C can be used for all kinds of cranes, hoists, and lifts.

By attaching sensors directly to equipment, all real time parameters from cranes can be transmitted to a monitoring device to synthesize and analyze.

Machine learning uses the gathered data to generate real time visual reports.

Update error reports quickly

View detailed information concerning each warning notification

Design working period of the hoist

Brake ware

Contactor

Load

Temperature

Runtime

Overload

E-stops

Over temp

Export ans share all reports of crane equipment

Our unique value proposition are

Remote management and monitoring solution for crane, help detect and control damage and parameters on the crane, be more proactive in the maintenance and maintenance plan.

Alert problems that may lead to failure, provide critical parameters and overload parameters to analyze the cause of failure.

Track the daily usage history of crane, report daily errors, provide charts and diagrams allowing easy detection if there are any abnormal changes.

Connection via internet allow report to be exported anytime, anywhere and in most popular formats like excel, words, pdf, etc

SSS4C helps increase safety conditions for crane technicians who will no longer need to work at dangerous heights to monitor cranes’ health.

Save time and energy for maintenance technician as climbing and working at height is time consuming and dangerous.

Save on machine downtime because this solution helps maintenance staff be more proactive in their work, diagnosing possible problems in advance.

Save by reducing the risk of production delays due to equipment failure, urgent repair services are often very expensive compared to pre-planned periodic maintenance.

Save by lowering the cost of human resources used for maintenance compare to the traditional human-based method of operation.